After X-mas and New Year 1989 the slipforming of the barrier halves commenced and went on through the cold dark winter. (Which I spent in warmer climes)

In Early summer 1989 the barrier had reached it’s full height and part of the top wall segments were put in place:

(The rest of the wall segments had to be installed offshore as the barrier had to maneuvered under bridges during installation)

Final step of preparations was to do a “test mating” to see that the two halves would actually fit together:

The largest fleet of large towing vessels ever used for one job was assembled in Aalfjord at midsummer. A total of 18 tugs, 9 for each half. (with one spare, just in case)

The first halve left just before midnight on mid-summers eve:

I was on the second half for the tow-out through the fjords and into the open ocean. Then making a wide arch to the NW of Ekofisk field and into the British sector of the North Sea due to a draft of 68 m. during tow. Tow-out weight for each half was abt. 230.000 m.t.

Weather enroute was perfect, with temperatures hitting over 20C.(Unusual for the N.S.)

We had a BBQ on the top slab during the tow:

How do you control 18 tugs simultaneously? The 4 Tow Masters (2 on each half) wrote down last order given to each tug on a whiteboard in our “control container”, while a time keeper kept records, sitting somewhere else. (There were three containers holding the various positioning equipments and technicians)

By the time we approached the Ekofisk Complex the weather had deteriorated and we had to hold for a few hours before making final approach:

The first half had already been positioned and set on bottom. Now for the difficult part; swinging the second half into position under bridges, using a “docking pin” as pivoting point, and “mating” the two with an allowed tolerance of 7.5 Cm. from ideal “0”.

Some of the tugs were used as “winch platforms”, meaning that they picked up a mooring wire from stationary points (Pile anchor) which was brought into a Smit bracket installed at the bow especially for this operation. Some other tugs were “active”. (I.e used as “ranging tugs” and escape)

Second problem was that the seabed was sloping towards the Complex from all direction due to subsiding from pumping out oil and gas, and the weigh of the Ekofisk Tank. (>1 Mill. m.t.)

Ballast had to be pumped into the cells during the approach to slide under the bridges, yet with a 1.0 m. UKC at all times to avoid damaging the pipelines running in and out of the Complex. (Did I mention that the Complex was producing and exporting at full blast during this operation??)

Despite all our “state-of-the-art” instrument, (incl. Lasar and Sonar) final positioning was done using a measuring tape and walkie talkies to give instructions to 7 boats and 2 fixed winches on the barrier .

We ended up 3.5 Cm. from the ideal “0”. Not bad when you consider that the total weight of the second half at that time had reached abt. 250.000 m.t.

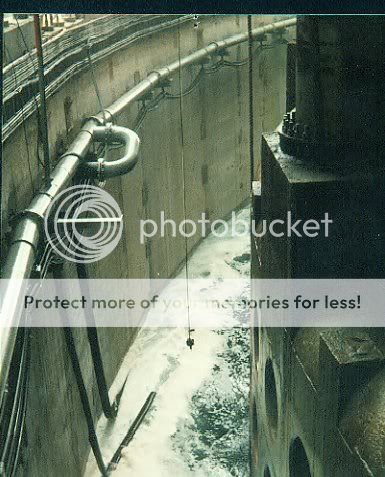

Here is a picture I took of the gap between the barrier and the Ekofisk tank after positioning:

And a picture from some other source, showing the Ekofisk Complex with the barrier in place and completed:

It is still there today, but the Central Processing unit has been removed and both the tank and it’s barrier is of no importance any more:

I still maintain that this is the most complex (some may say crazy) Offshore Marine Operation ever conducted.