The kind where you could close all windows in the wheelhouse and they would never notice. Glued to the radar and other screens…

We were in Bahrain in August, it was hot and dry, even the locals were saying it was hotter than usual. I left my air conditioned office to have a look around and by the time I’d made it aft I thought my hair was going to catch on fire in the sun.

When I made it back I went to the wheelhouse to check the wet/dry temps. The mates were logging them as the same - 100% humidity. All the water had evaporated from the wet bulb reservoir and the mates were just logging the reading without a thought as to what the number mean.

As a third mate had a very good master/teacher. When we were in a little bit of traffic in good weather he would often come to the bridge. He would give us hand held VHF radio and tell us to stand watch on the wing. He would stay in the wheel house and act as our safety valve. But it was good practice to handle traffic without electronics.

All ships are stable when loaded correctly. Of course you can add cargo on the deck above waterline, and it will reduce stability until you heel too much. But when you have loaded your ship according all rules and it doesn’t feel OK. What to do? Sound all your double bottom tanks. Rust, corrosion, fatigue of the hull structure sinks most ships because seamen are lazy.

If the eye high is important for situation awareness, then the modern sea/river coaters must be ideal training ground:

I’ve never been able to detect a significant difference between calculated roll period and actual by timing the rolling period, too much error in the measurements. Diff between actual and calculated drafts is much easier.

I’ve sometimes wondered about a tool to measure roll period. Smart phones now being ubiquitous that might be the way to go.

The Application of a Smartphone in Ship Stability Experiment

Visual drafts is my goto as well to evaluate our stability program output.

This is a fun little app though:

That does look like a cool app & worth the investment considering it’s free. But how long before you got tired of it & quit using it? I admit if someone made an app for checking oil on a dipstick or guessing the correct size wrench to use on a bolt or nut I might download them & use 'em a little but I’ve pretty much mastered the skills of reading a dipstick & guessing what wrench to grab. I hope most seasoned bridge officer have a feel for their vessels & only use the app for a little bit as a novelty. Maybe junior officers could use it to build their base line then grow bored with it once they know what the screen would say before they could take their phones out of sleep mode?

Apparently on some ships (maybe all?) mates have to record the sea conditions every 4 hrs in the log at the beginning or end if their watch. I remember 1 Colombian mate I worked with who was terrible at reading swell size. He could get the other numbers like wind speed & direction from the electronics but write down goofy numbers for sea conditions. After hearing guys kid him a few times I think the solution was to tell him to leave that space blank & judge the sea sizes with another officer until he got the hang of it. I can imagine a stability app would be good for a case like that. I hate to think today, 10 years later that Colombian mate still needs another mate to tell him how high the seas are.

Easiest way to log swell height is look to see what the last watch logged. If it’s gotten better or worse adjust accordingly.

A good way to calibrate judgment from the bridge wrt to sea/wave height is to go down to the main deck and have a look.

On offshore ships a rule of thumb is to time the pitch from bottom to top of a wave and that’s the Hs in metres, roughly.

Maybe a better example would be the use of a torque wrench. Most jobs can be done without one.

Other jobs might require more “feel”, only done by experienced mechanics having calibrated their feel from previous experience with a torque wrench (or from stripping threads). A few jobs with stringent requirements and expensive equipment need to be done using the torque wrench every time.

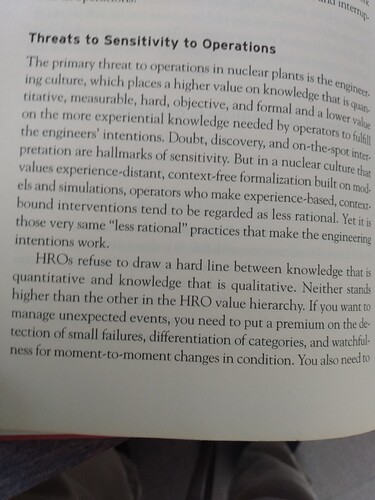

This is from “Managing the Unexpected” by Weick and Sutcliffe.

About operations in nuclear plants but not drawing a hard line between quantitative and qualitative is relevant to the discussion.

Quantitative data is information about quantities, and therefore numbers, and qualitative data is descriptive, and regards phenomenon which can be observed but not measured, such as language.

I still pull it out once in a while just for shits and giggles.